LIGHT PLATE VB

The Smart-Fit LED Upgrade

The Smart-Fit Light Plate VB is the only product on the market specifically designed and developed for retro-fit installation within 450W Metal Halide, pyramidical lens enclosures. Now in its third generation it delivers guaranteed outstanding results without the need to replace your original luminaire enclosure and lens.

Light Plate VB Luminaire Performance Up To:

27,000lm - 150 lm/W | L90 / 100,000hrs*

Smart Fit LED Upgrade

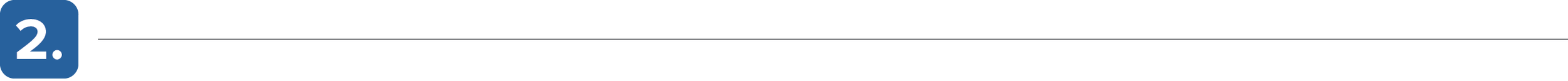

Light Plate VB is designed to adapt to the depth and overall size of your existing enclosure.

Supplied in two parts an LED light engine and vented lid and stainless steel mesh to prevent the ingress of insects. The lid is custom sized in factory to ensure the perfect fit and operational efficiency.

Install simply in minutes.

Once the existing components are removed from the fitting simply rivet the angled brackets to the sides of the original enclosure, adjust and lock the brackets to size, position and anchor in place with bolts provided. Plug in the quick connector, position the lid and connect to power. Its as simple as that.

Note:

Powder coated steel bracket with retaining bolts for seismic support and compliance.

Three power tray options.

The power tray of the Light Plate shares the same heat sink and LED array as the latest Soffito product range, offering all of the benefits possible within the limits of your legacy lens*.

100W | 15,000lm

150W | 22,500lm

180W | 27,000lm

Note:

Adjustable bar, locks into position at the perfect size of your legacy enclosure, positioning the light source in the optimum position.

* Nominal output (lux) at Ta 25ºC, based on CCT 5,000K, Ra85, R9≥10. Ra95 multiplier 0.92 before losses subject to legacy lens.

Primary Optics.

The primary lens prevents damage to the LEDs during installation and eliminates spotting and glare, on white and stainless surfaces. The Light Plate VB is designed to meet all the challenges of the food processing industry and the power to raise and maintain lux levels and improve site safety.

Eliminates dangerous reflections and glare

Reduces work place accidents

Eliminates shadows around complex machinery and aerial clutter

Soft light + precise colour rendering improves visual acuity

Improves accuracy during inspection and sanitation

Custom lid direct from factory

The vast majority of 200-450W MH fixtures feature square or rectangular tops generally with existing lids simply measure the outside of your existing fitting. For Isollux to manufacture a custom lid simply measure the outside of your existing fitting and we will do the rest.

Odd shape box?

Take a photo and contact us for options that include a frame that fits around your luminaire to accommodate our standard lid size or an alternative vented solution.*

Note:

IP67 brass pin barrel connector for easy connection to existing mains power supply.

SELV out to power tray with quick connector provides easy access for cleaning and maintenance.

*CAD fees apply for shaped enclosure designs that cannot utillise the standard vent and may be subject to MOQ

More Details

LED Performance

ISOLLUX HE LED CHIP

184lm/W @ Ra85

100,000Hrs/L90

Ra85 | Ra95 | 3000K | 4000K | 5000K | 6000K

The Isollux HE LED Chip is powerful and long-lasting. Capable of delivering 184 lumens per watt (before loses) and the ability to last four times the industry standard with proper driver management*. The HE Chip delivers an exceptional ROI, with a low environmental impact and class leading performance.

Isollux HE is a dual die chipset, operated at less than 50% of its peak drive current, designed to deliver the maximum service life and efficacy of the luminaire. It has an exceptionally long service life of L90 100,000Hrs specified to optimise the luminaire performance. It is ideal to support long term maintenance strategies minimising waste (See maintenance section below).

Colour Rendering

Ra95 for colour critical applications.

Available in four standard colour temperatures, from 2,700~6,000ºK with superb colour rendering at both Ra85 and Ra95

@ Nominal Ra95 / 4,000k (CRI 94.2)

Ra85 boosts efficacy

Specifying Ra85 increases lumen output whilst maintaining full colour rendering, high R9 with neutral bias, perfect for general industrial commercial and retail applications.

@ Nominal Ra85 / 4,000k (CRI 85.9)

*Factor 0.92 at Ra95 and increase luminaire wattage accordingly to maintain required lux levels.

Key Benefits

External LED driver with quick connector to luminaire positioned to minimise thermal load on LEDs and maximise system service life.

Vented lid with stainless insect mesh produces natural convection current inside fixture to minimise thermal stress on LEDs.

Factory made custom lid to suit the exact size of your existing enclosure.

Food grade, shatter proof and impact resistant primary lens creates a glare and spot free wide angle distribution.

Dual chip high density HE LED arrays, optimised for long term performance with chemical and moisture resistant coating

After reflux soldering, each PCB is dipped and cured with a chemical and moisture resistant coating.

Installation

A simple replacement option

Preparation of original fixture.

Ensure all power to the original luminaire is permanently disconnected prior to installation. Once power is disconnected internal obstructions such as lamp holders, cables and brackets can be removed safely.

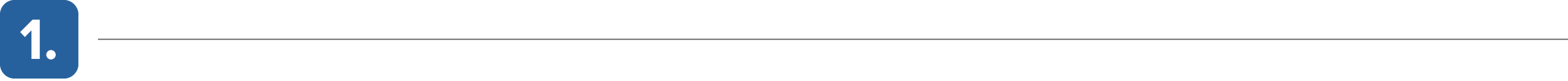

Remove the lid from the original luminaire. If necessary cut the top away, using suitable tools and protection (removing all sharps). Ensure the surface is clean and level. Once preparation is complete you should be left with the original pyramid lens with a box size of approximately 590mm x 590mm and a minimum height of 300mm with no internal obstructions. Clean the original lens, remove any detritus and perform a visual inspection of the lens for damage.

1. Permanently disconnect and isolate electrical components prior to stripping the enclosure

2. Visually check the stripped enclosure and original lens for damage

3. Fix brackets provided at equal heights on either side. For best results, LED should be at or below the level of the opening when installed (subject to lens shape).

4. Adjust width of arms to provide a suitable footprint onto the brackets approximately 4mm inside the overall width of the enclosure and lower into position

5. Lock the Light Plate to the brackets at each corner using the screws provided for seismic restraint.

6. Cover with lid provided ensuring the length of the vent runs parallel with the lens and heat sink below. Connect and test before taping lid to enclosure to seal.

Product Sizing

Max Width: 650mm x 650mm | Min Width: 525mm x 525mm | Min Height: 70mm

Maintenance

Maintenance makes sense, financially, ecologically and practically. Light Plate HE delivers performance of up to 200,000 L70, when combined with simple fast and efficient driver replacements to obtain maximum life of your fitting (See Lifetime Sustainability below).

It is essential to keep the insect screen that covers the vent clear of obstruction to ensure air flow remains unobstructed. For this reason we recommend taping the lid with white tape and marking the install or maintenance date. All environments differ, and product lifetime is subject to ambient temperature and unrestricted air flow.

Lifetime Sustainablilty

Isollux HE dual chip technology increases LED lifetime up to 200,000 Hrs, with maintenance kits to extend the practical life of the luminaire. Simple, efficient and financially beneficial.

Reduces total cost of ownership maximising ROI and NPV

Reduces land fill, manufacturing and supply related carbon footprint by up to 640%

Delivers a longer practical performance life (L90 >100,000 Hrs* - L70 > 200,000 Hrs)

Supports planned and unscheduled maintenance to the maximum life of the fitting

Minimizes downtime with easily maintained and replaceable parts

Ensures continuity of fixtures on site

Components easily dismantled at end of life for recycling

Packing and Shipping Information

LIGHT PLATE VB

Carton Weight: 13kg

Carton Dimensions: 62cm x 61cm x 18cm

Units Per Carton: 1

Product Net Weight: 11kg

*All sizes and weights are for shipping and delivery purposes only and can to change depending on specification. For an exact size and weight contact Isollux directly.

Download: Brochures | Instructions | IES Files

Light Plate VB Brochure

*HE Chipset L90 Lifetime calculated using 9,000hr independent LM80 photometry report, citing zero failures, using the Energy Star TM-21 protocol. Calculations are based on ambient temperatures of 25ºC. Assumes driver replacement as routine maintenance event with driver replacement schedules subject to, power quality, frequency of switching cycles and average to peak ambient operating temperatures. Assumes driver replacement at midpoint of lifecycle, with the calculated MTFB 192.2K hrs min. MIL-HDBK-217F (25°C) based on the 100W 1500mm TPA/TPH. Average driver life 62,000Hrs.