PROLINE LINEAR LOW BAY

Specifier Series

PROLINE is the result of 10 years research into material science, mechanical engineering, electronics and thermal management. It provides unparalleled performance and protection. Seismic safe surface, machine or suspended mount to virtually any surface.

Proline Luminaire Performance Up To:

21,750lm - 145 lm/W | L90 / 100,000hrs*

Proline Ambient Temperature Range:

-30ºC / +40ºC*

Five Lengths | Eight Power Options:

With the powerful HE chipset (details below), five lengths and eight power options, we are confident that you will the model, performance and output you need to deliver a perfect and lasting lighting.

PCX Power and Size options (145lm/W)

600mm

40W | 5,800lm

900mm

60W | 8,700lm

1200mm

60W | 8,700lm

80W | 11,600lm

1500mm

100W | 14,500lm

120W | 17,400lm

2000mm

120W | 17,400lm

150W | 21,750lm

TPX Power and Size Options (135lm/W)

600mm

40W | 5,400lm

900mm

60W | 8,100lm

1200mm

60W | 8,100lm

80W | 10,800lm

1500mm

100W | 13,500lm

120W | 16,200lm

2000mm

120W | 16,200lm

150W | 21,750lm

*Up to five times the life of PC ABS or PMMA blends, service life subject to concentration, duration at rest and rinse cycles. Lumen performance and Maximum Ambient Temperature subject to model and specification.

Proline TPX

Extreme chemical and impact resistance, food-safe and UV stable, fully serviceable enclosure built to withstand high pressure, high temperature washdown to IP69K.

Proline TPX was developed specifically for increased resistance to sanitisers including alcohols, peroxides, aldehydes, quaternary compounds, alkyl amines and chlorine releasing compounds. The product is fully enclosed and protected by a high performance polyester alloy sheath and end caps offering superior resistance to:

Acetic Acid

Ethoxylated Alcohols

Amines

Benzalkonium Chloride

Benzyl Alkyldimethyl Chlorides

Disodium Metasilicate

Dodecyldimethylamine oxide

Ethanol

Hydrogen Peroxide

Hypochlorus Acid

Peroxyacetic Acid

Potassium Hydroxide

Quaternary Ammonium Compound

Secondary Alkanesulphonates

Sodium Carbonate

Sodium Dodecylbenzene Sulfonate

Sodium Hydroxide

Sodium Hypochlorite

Proline PCX

IP69K Polycarbonate, impact resistant, food-safe, UV Stable, fully serviceable

V-0 fire rated enclosure. Suitable for high pressure wash down, wet, damp and dusty conditions.

Manufactured from tough, durable impact resistant Polycarbonate, the PCX provides an economical option, where the extreme chemical resistance capabilities of TPX are not required. It is suitable for most general applications such as freezers, food preparation areas, parking facilities and general under veranda applications.

PCX can also be supplied with our formidable range of ZigBee wireless sensors, to deliver sophisticated wireless lighting control to individual or linked units. With the power to provide ample light in warehouses and workshops..

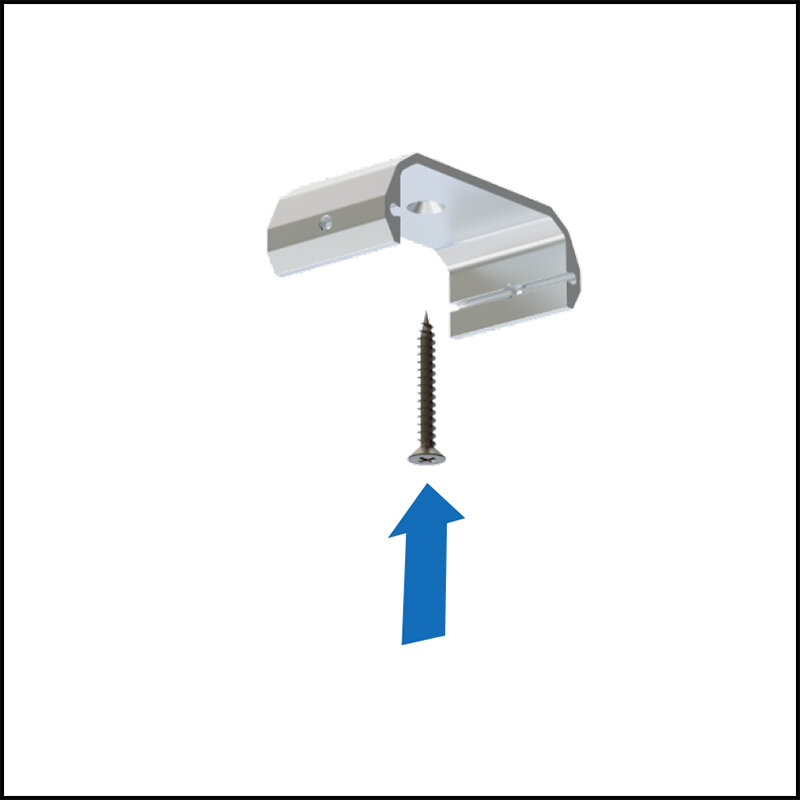

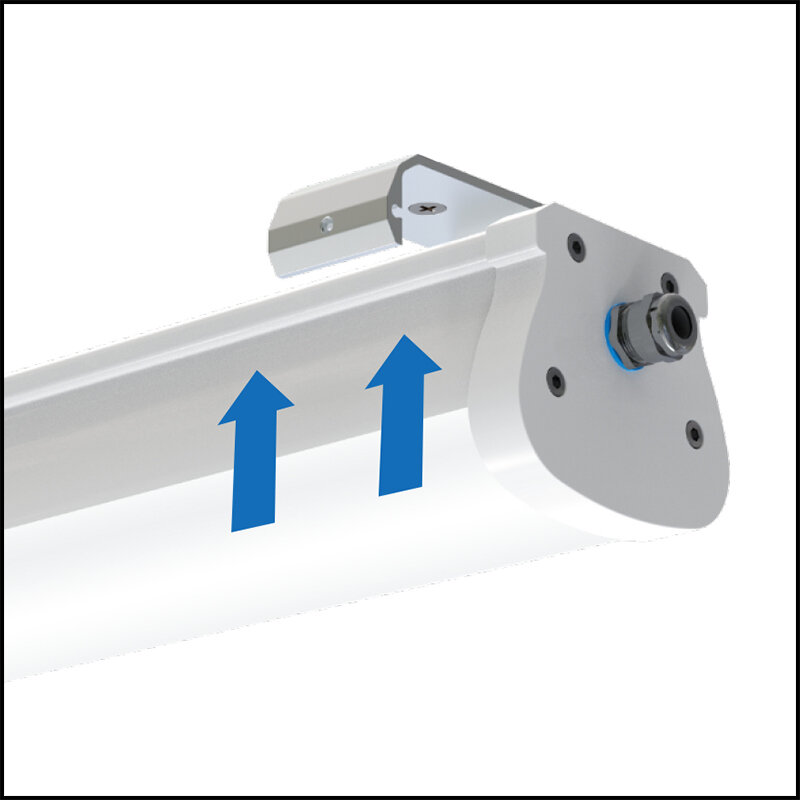

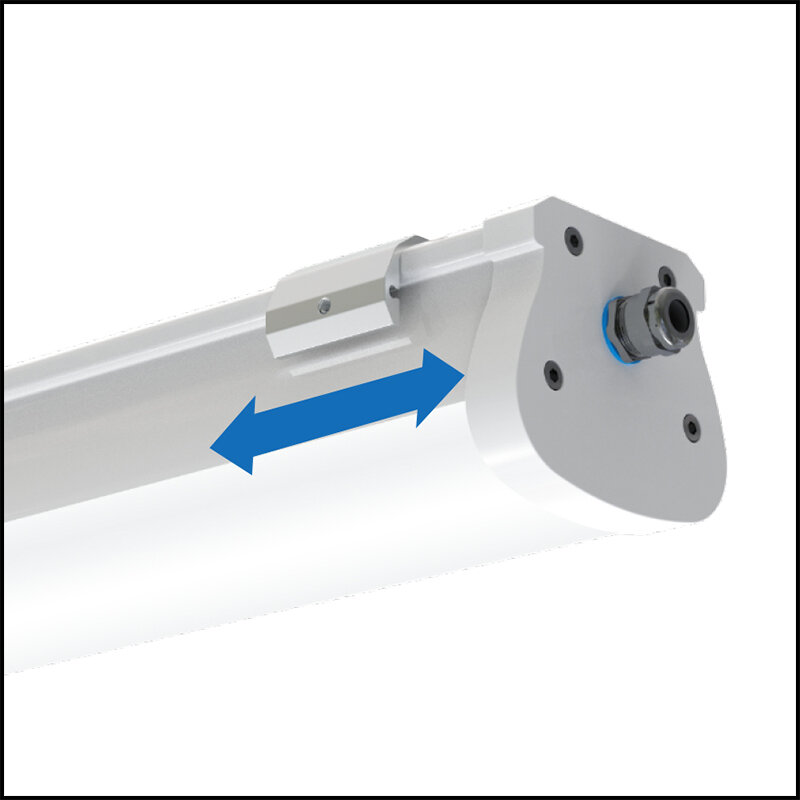

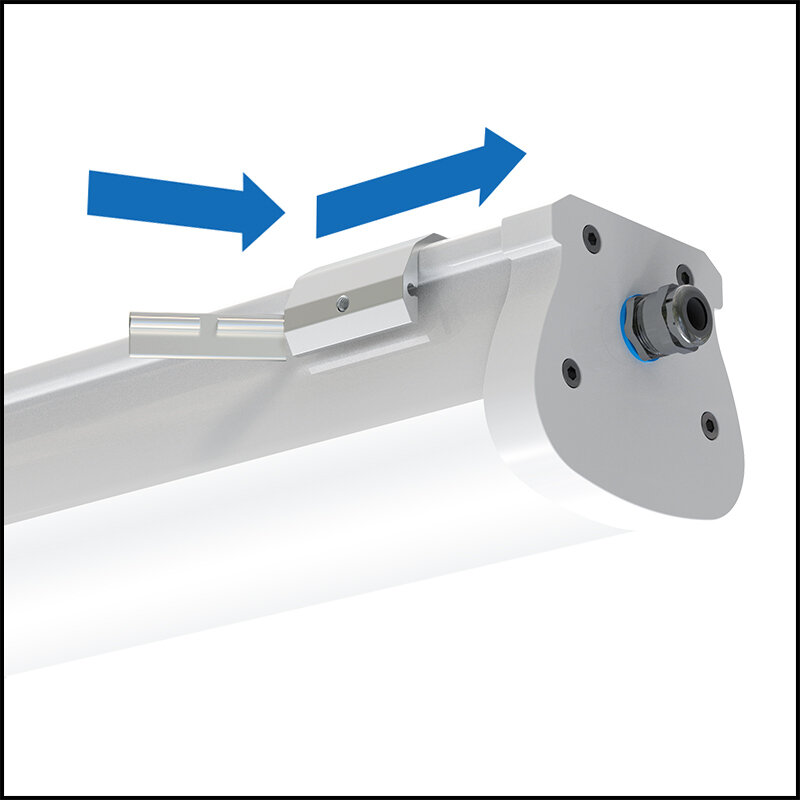

Simple and secure; surface mount with optional suspension kit

Proline features a unique bracket design, which provides a seismic secure, quick release connection between virtually any horizontal or vertical surface, allows direct mount options to machinery, ceilings and walls using the patented “key and clamp” mechanism.

The optional stainless steel suspension kit*, fixes directly to the bracket in seconds. To provide a sliding grip with easy and intuitive height adjustment.

*The hanging kit is not suitable for product applications which involve pressure washing.

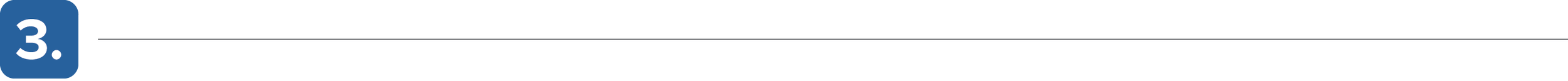

Diffuse light output

The lens-sheath provides two important functions. Encapsulating and protecting the electronic components, whilst eliminating glare and spotting.

Eliminates dangerous reflections and glare

Minimises shadows around complex machinery and aerial clutter

Improves visual acuity for quality control and sanitation.

Ra95 for colour critical applications.

Available in four standard colour temperatures, from 2,700~6,000ºK with superb colour rendering at both Ra85 and Ra95.

Proline PCX-HE-495-100W (IES LM79 TM30-18)

≥135lm/W @ Nominal Ra95 / 4,000k (CRI 94.2)

Ra85 boosts efficacy

Specifying Ra85 increases lumen output whilst maintaining full colour rendering, high R9 with neutral bias, perfect for general industrial commercial and retail applications.

Proline PCX-HE-485-100W-DA (IES TM30-18)

≥145lm/W @ Nominal Ra85 / 4,000k (CRI 85.9)

Ambrite™

Elimination of Blue Spectrum (≤500nm)

Ambrite™ is a new LED chipset from Isollux that effectively eliminates blue spectrum below 500nm. Ambrite™ chipsets deliver up to 129lm/W. Outperforming products that rely on filters or optics to control blue peak emissions.

Ambrite is perfect for Photosensitive manufacturing, pharmaceuticals, brewing and exterior applications where insects present a significant commercial risk, such as loading bays.

To order, select the Proline protection grade required (TPX/PCX) and specify AMB in place of Ra/CCT

Luminaire Performance Up To:

19,350lm - 129 lm/W*

Ambient Temperature Range:

-30ºC / +40ºC*

*Up to five times the life of PC ABS or PMMA blends, service life subject to concentration, duration at rest and rinse cycles. Lumen performance and Maximum Ambient Temperature subject to model and specification.

Isollux Ambrite™ LED offers two distinct environmental colour tones for photo-sensitive applications such as high performance 3D printing, photo-lithography and pharmaceuticals. Both options eliminate wavelengths below 500nm with only moderate differences in spectral performance.

Customers can choose the most appropriate colour for staff by specifying either Ambrite™ AMX (Pictured above) or the warmer Ambrite™ AMH (below).

Soffito SLP is easily customised to provide dual chip options to a single luminaire, making total control of the lighting environment available at the flick of a switch, ideal for dark rooms or small laboratories.

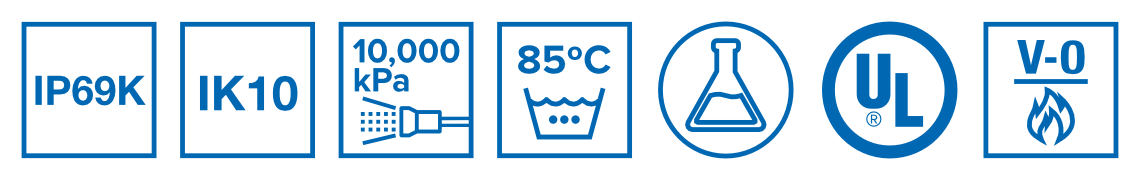

How and why we de-stress key components to achieve maximum service life and optimum value

Isollux HE Chipsets are backed by independent photometry reports including, LM79 for colour rendering and IES files; and LM80 (10,000Hrs) predictive endurance tests. The LM80 reports allow engineers to accurately predict the expected performance of individual LEDs across a given range of thermal and electrical conditions. Typically manufacturers use this data to run the LEDs in circuit at or near peak loads to minimise cost to market by reducing component count.

Our engineers use the test data, as a bench mark from which to de-rate components, increasing the number of LED in circuit to optimise performance. Increasing LED count allows us to reducing drive current lowering the thermal load on all critical components, including the LED die, driver, PCB and electrical connections. This approach delivers significant gains in, efficiency, performance and reliability, in particular maximising the service life of each of the key components.

Proline-HE Drive Current | ƒ

The illustration below scales the maximum allowable forward current for the Isollux HE chipset and the drive current used in the independent LM80 reports compared to the actual drive current used to power Proline PCX (480 LED HE High Density Array per Metre).

Proline-HE Case temperature TC

The illustration below scales the case temperatures used in the LM80 reports tested at 150mA, compared to the actual case temperature of production models driven at 44mA. The combination of reduced If and Tc significantly increases performance and reliability.

Customer benefits of de-rating components

De-rating components reduces the Total Cost of Ownership (TCO) ie it reduces the long term cost of both operating and maintaining a lighting solution. Rather than focusing on headline price. TCO includes the capital cost of the luminaire and the cost of installing and maintaining the fixture.

The cost related to regular replacement of LED fittings is often overlooked. In the case of clean rooms it also generally results in significant business interruption to complex and sensitive production facilities. Adding the additional risk of performance caveats such as B’ratings and the costs quickly spiral. (See illustration below)

Isollux products are designed to surpass warranty without caveats, even when installed in challenging environments at high ambient temperatures. It provides specifiers with the option to compare operational savings over extended periods. Up to 200,000 Hours L70 when using lighting controls or a lower light loss factor, with the option to increase driver output retrospectively at the mid point in the product life cycle where controls are not an option.

Performance life cycle comparison

Solid Construction with Food Safe Materials

- 1.

PCB and LED array is dipped and cured with a chemical and moisture proof coating after reflux soldering. The HE LED Chipset is optimised for performance and lumen maintenance.

2.

Food grade IK10 impact resistant lens sheath rated to IP69K. Material and capabilities differ between TPX and PCX.

3.

IK10 impact resistant re-enforced end caps provide firm anchor and base for seal. Material and capabilities differ between TPX and PCX.

4.

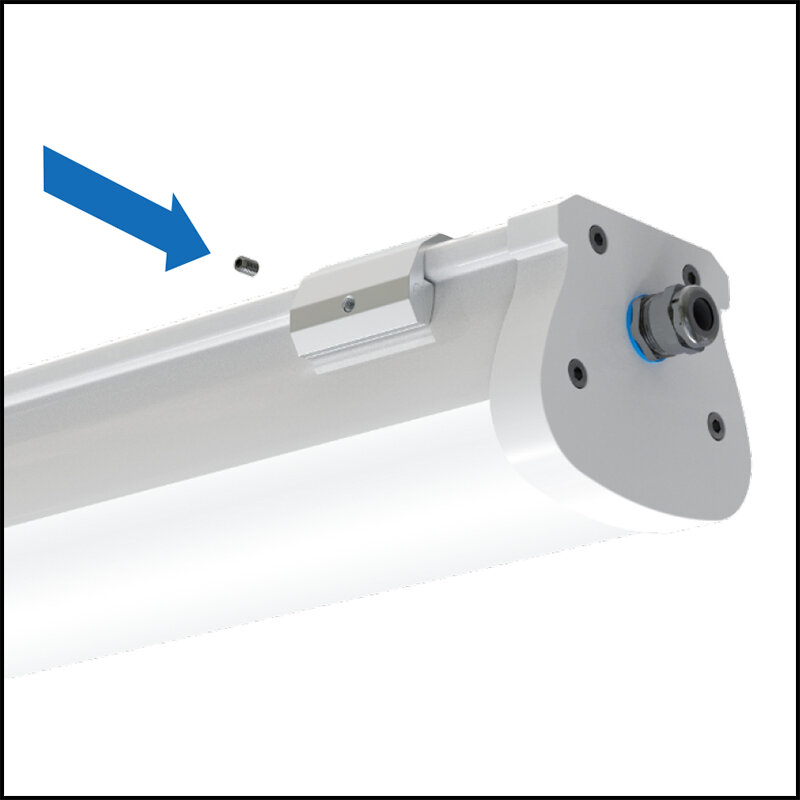

Earth Tag and SS M6 machine head screw provides earth continuity across all metal parts.

- 5.

SS IP69K breather valve balances pressure and eliminates condensation.

6.

M6 SS Self-tapping machine head screw, sealed to face with blue EPDM O-ring.

7.

Food Grade, EPDM chemical resistant gasket effectively seals the Proline up to IP69K

8.

6063 Aluminium heatsink, efficiently transfers thermal load through the outer case, whilst providing Proline with a rigid and strong inner core.

More Details

Flush or Surface Mount Installation

Wireless Control

Wired or wireless controls to optimise service life and efficiency

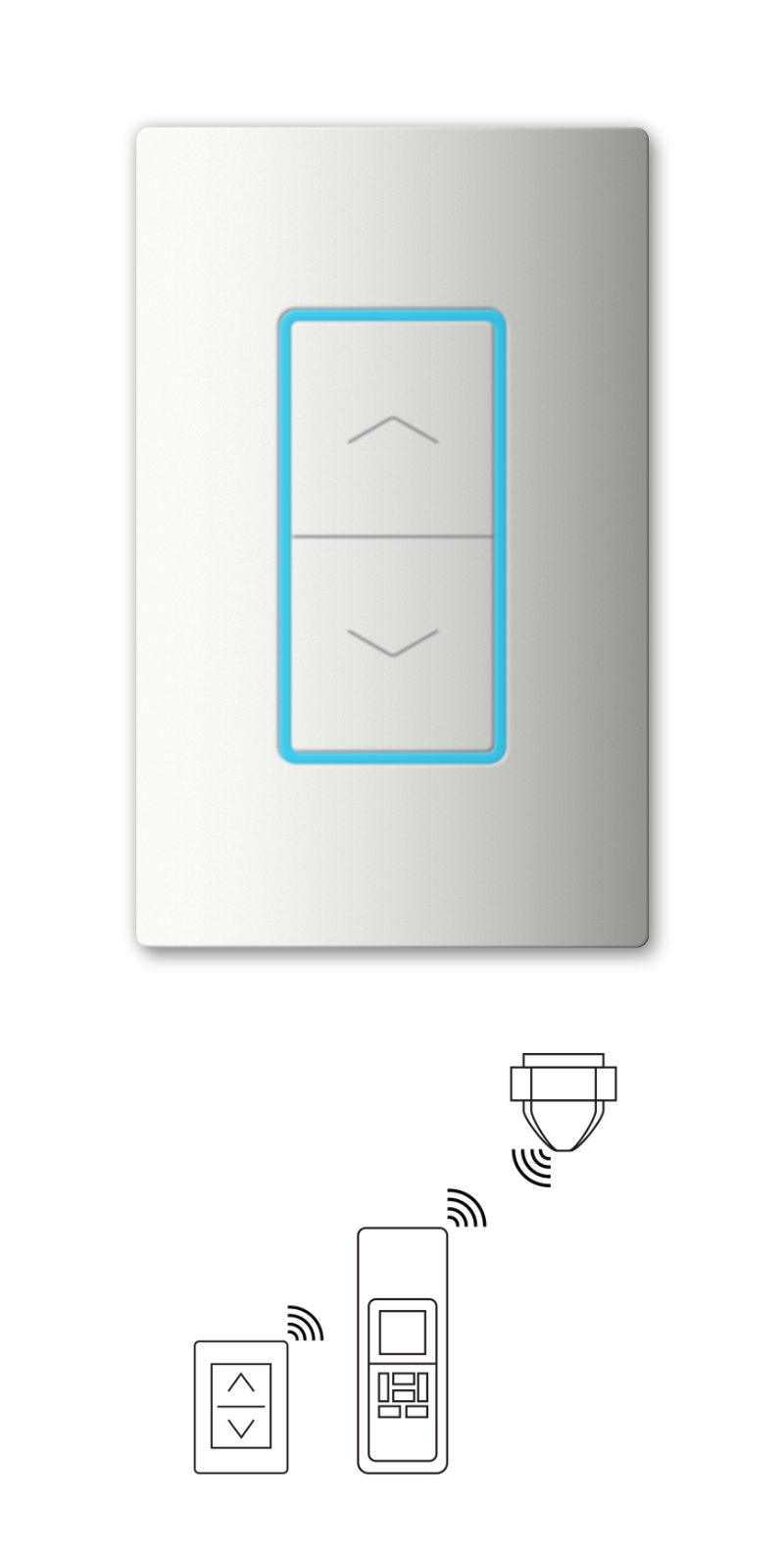

The Proline PCX supports both wired and wireless control options to minimise running costs associated with warehouse or storage areas. From simple set ups with multiple units hard wired and switched via occupancy sensors to fully optimised wireless controls

Reliable mesh network without internet connection

The optional OS-NET ZigBee control system delivers unparalleled control of luminaire without the need for complex programming or data management. Simply program via a point and push infra-red remote to select individual lights or program entire groups instantly.

Update or change groups at any time, add multiple luminaire to groups or single luminaire to multiple groups.

No ongoing fees, no wireless updates, no complex programming or mapping required. Simple stand alone efficient lighting controls to maximise your energy savings.

Wireless wall switches provide practical over-ride.

Your facility may only require low lux levels for most of the day with casual traffic, and none when empty. Occasionally however you need maximum power for a short burst of activity. The OS-NET wireless wall switch provides a simple over-ride command to raise lux levels instantly for a time you choose.

Easy to install, no direct connection to the luminaire circuit required It provides an invaluable link between one or more luminaire and the operator on the ground.

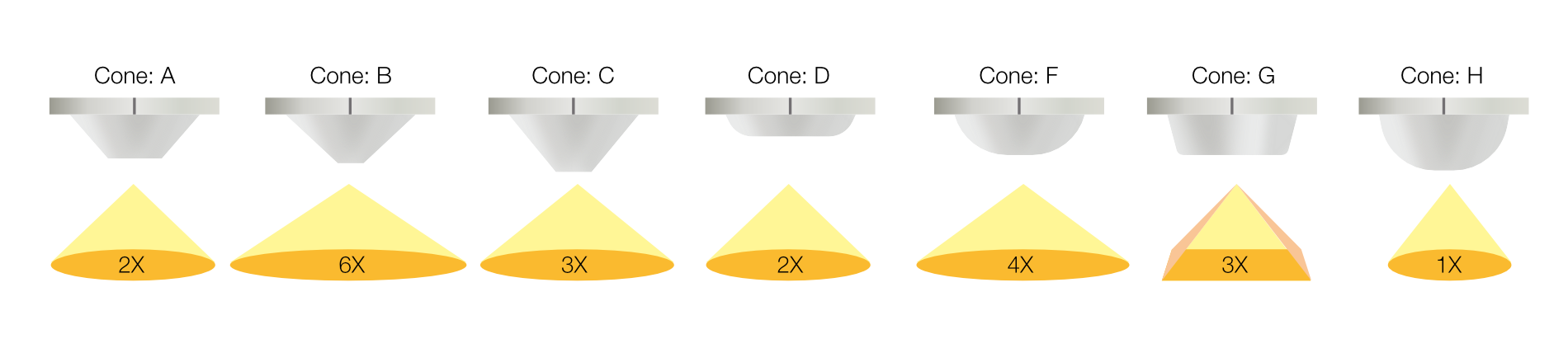

Multiple lenses optimize detection.

All sensors supplied with the TPX family feature hot swappable lenses to fine tune and target detection exactly. The lens system offers a range of options to a maximum height of 14m.

Maintenance

Maintenance makes sense, financially, ecologically and practically.

Our team can explain the true cost of short term thinking and help your business reduce costs and achieve a sustainable future.

Proline - Maintenance Kits

Average installation to maintenance cycles*

Outer Sheath

35,000 - 70,000 Hrs

End Caps and Seals

35,000 - 70,000 Hrs

Driver Tray and Connections

50,000 - 100,000 Hrs

LED Array (Not Shown)

200,000 Hrs L70 (HE Chipset)

*Maintenance cycles are dependent on ambient temperatures, frequency of wash cycles, application method, duration and concentration of chemicals used for sanitation and wash down and the hours of operation and switching of the luminaire.

Packing and Shipping Information

PROLINE 0600

Carton Weight: 10kg

Carton Dimensions: 62cm x 30cm x 30cm

Units Per Carton: 4

Product Net Weight: 9.2kg

Product Weight: 2.3kg

PROLINE 0900

Carton Weight: 14kg

Carton Dimensions: 92cm x 30cm x 30cm

Units Per Carton: 4

Product Net Weight: 13.2kg

Product Weight: 3.3kg

PROLINE 1200

Carton Weight: 18kg

Carton Dimensions: 127cm x 30cm x 30cm

Units Per Carton: 4

Product Net Weight: 17kg

Product Weight: 4.25kg

PROLINE 1500

Carton Weight: 21.7kg

Carton Dimensions: 151cm x 29cm x 29cm

Units Per Carton: 4

Product Net Weight: 20kg

Product Weight: 5kg

PROLINE 2000

Carton Weight: 27.8kg

Carton Dimensions: 208cm x 30cm x 29cm

Units Per Carton: 4

Product Net Weight: 26kg

Product Weight: 6.5kg

*All sizes and weights are for shipping and delivery purposes only and can to change depending on specification. For an exact size and weight contact Isollux directly.

Download: Brochures | Instructions | IES Files

Proline Brochure

Proline Instructions

Proline IES Files

Proline Photometry

*HE Chipset L90 Lifetime calculated using 9,000hr independent LM80 photometry report, citing zero failures, using the Energy Star TM-21 protocol. Calculations are based on ambient temperatures of 25ºC. Assumes driver replacement as routine maintenance event with driver replacement schedules subject to, power quality, frequency of switching cycles and average to peak ambient operating temperatures. Assumes driver replacement at midpoint of lifecycle, with the calculated MTFB 192.2K hrs min. MIL-HDBK-217F (25°C) based on the 100W 1500mm TPA/TPH. Average driver life 62,000Hrs.