Soffito SUP

The Soffito Upgrade Kit

Breathe new life into Soffito without the cost and disruption of a full product replacement.

It’s been 8 years since we launched Soffito with the oldest products operating continuously for more than 70,000Hrs, some, are beginning to show their age.

So while you may not be ready yet: the Soffito Upgrade Kit delivers the latest performance gains and product enhancements, whilst avoiding the cost and distruption of a full replacement.

Soffito SUP Luminaire Power Increase:

Now 140 lm/W | L90 / 100,000hrs*

Was 120lm/W L70 / 65,000hrs

SUP Kit Power Options:

|

100W - HE 14,280lm |

150W - HE 21,300lm |

180W - HE 25,560lm |

We’ve made it easy

The Upgrade Kit, installs in minutes, just eight screws, power connection and a FIVE YEAR Warranty on all parts replaced.

Suitable for all exisiting Soffito

The New Soffito (SUP) UPGRADE KIT is fully compatible with all models of Soffito. Including Soffito connected to DALI UPS or the EM-IP65-30W, 90min Emergency Pack.

What’s in the box:

NEW High Performance dual die LED Chipsets

NEW Variable Output LED Driver

IP67 Barrel Connector – to existing mains power

IP65 Quick Connectors to light engine

Stainless Steel cable entry

Stainless Steel self tapping screws to secure top

NEW 5 Year Warranty*

Performance Gains:

Up to 45% increase in lux levels* combined with L90 ≥100,000 Hrs performance ensures years of additional service and a 10% reduction in power consumption.

*Compared to original 200W Soffito in continuous operation since install.

How and why we de-stress key components to achieve maximum service life and optimum value

Isollux HE Chipsets are backed by independent photometry reports including, LM79 for colour rendering and IES files; and LM80 (10,000Hrs) predictive endurance tests. The LM80 reports allow engineers to accurately predict the expected performance of individual LEDs across a given range of thermal and electrical conditions. Typically manufacturers use this data to run the LEDs in circuit at or near peak loads to minimise cost to market by reducing component count.

Our engineers use the test data, as a bench mark from which to de-rate components, increasing the number of LED in circuit to optimise performance. Increasing LED count allows us to reducing drive current lowering the thermal load on all critical components, including the LED die, driver, PCB and electrical connections. This approach delivers significant gains in, efficiency, performance and reliability, in particular maximising the service life of each of the key components.

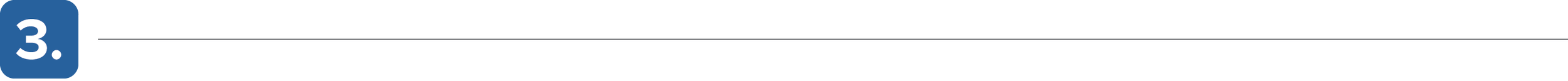

SUP-HE Drive Current | ƒ

The illustration below scales the maximum allowable forward current for the Isollux HE chipset and the drive current used in the independent LM80 reports compared to the actual drive current used to power Soffito SUP (1,440 LED HE High Density Array).

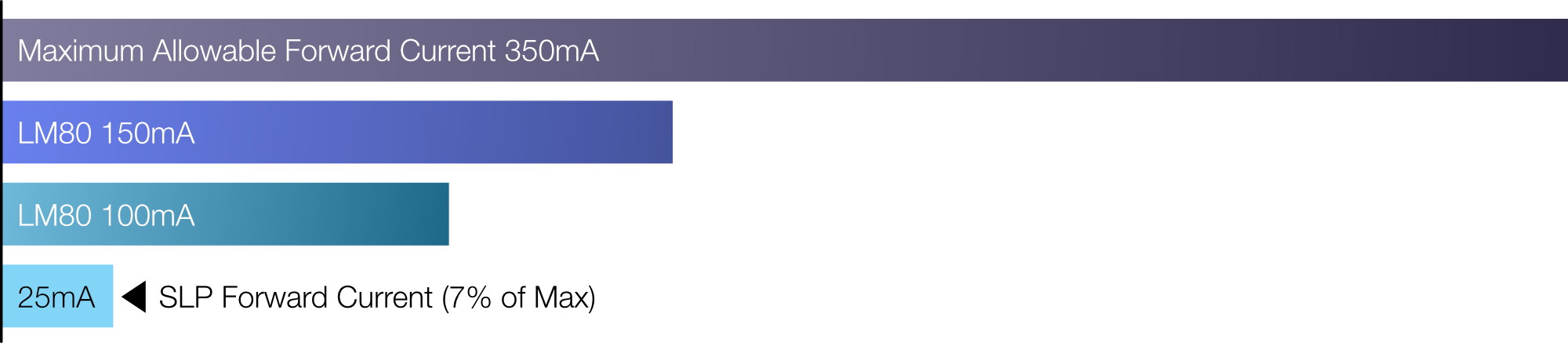

SLP-HE Case temperature TC

The illustration below scales the case temperatures used in the LM80 reports tested at 150mA, compared to the actual case temperature of production models driven at 25mA. The combination of reduced If and Tc significantly increases performance and reliability.

Customer benefits of de-rating components

De-rating components reduces the Total Cost of Ownership (TCO) ie it reduces the long term cost of both operating and maintaining a lighting solution. Rather than focusing on headline price. TCO includes the capital cost of the luminaire and the cost of installing and maintaining the fixture.

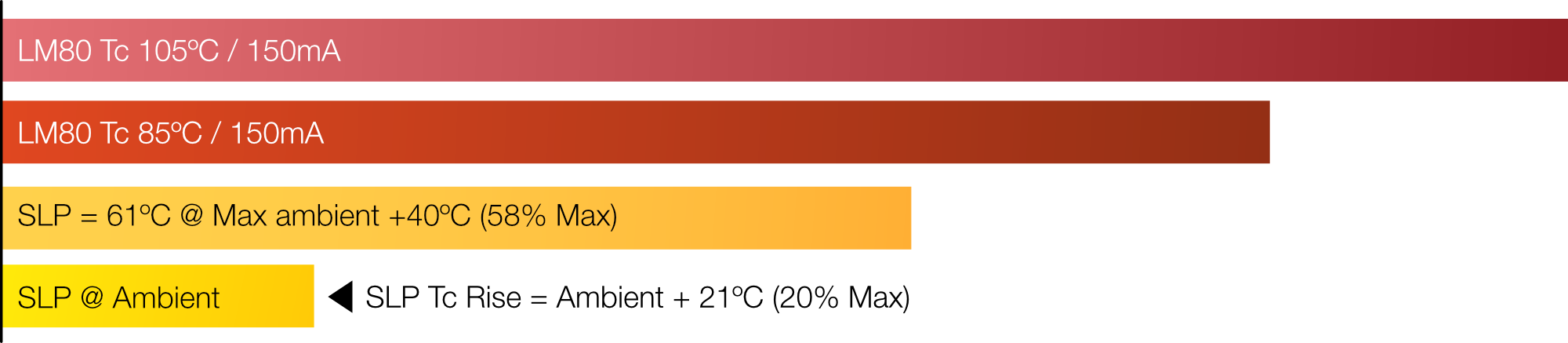

The cost related to regular replacement of LED fittings is often overlooked. In the case of clean rooms it also generally results in significant business interruption to complex and sensitive production facilities. Adding the additional risk of performance caveats such as B’ratings and the costs quickly spiral. (See illustration below)

Isollux products are designed to surpass warranty without caveats, even when installed in challenging environments at high ambient temperatures. It provides specifiers with the option to compare operational savings over extended periods. Up to 200,000 Hours L70 when using lighting controls or a lower light loss factor, with the option to increase driver output retrospectively at the mid point in the product life cycle where controls are not an option.

Performance life cycle comparison

Ra95 for colour critical applications.

Available in four standard colour temperatures, from 2,700~6,000ºK with superb colour rendering at both Ra85 and Ra95.

Soffito SLP-HE-495-100W (IES LM79 TM30-18)

≥120lm/W @ Nominal Ra95 / 4,000k (CRI 94.2)

Ra85 boosts efficacy

Specifying Ra85 increases lumen output whilst maintaining full colour rendering, high R9 with neutral bias, perfect for general industrial commercial and retail applications.

Soffito SLP-HE-485-100W-DA (IES TM30-18)

≥140lm/W @ Nominal Ra85 / 4,000k (CRI 85.9)

Designed for the life of your building

One of Soffito’s most important design features is the ability to upgrade or replace all electrical components without breaking the seal to the room below. Eliminating disruption to sensitive and critical environments during both scheduled or unscheduled maintenance.

Soffito features a flat, frosted, impact resistant polycarbonate lens, that is easily replaced if damaged or customised for special applications..

We’re committed to your “right to maintain

Isollux products offer an exceptionally long service life; and Soffito SLP is no exception, delivering up to 100,000 Hrs continuous service between maintenance events. Eventually however light losses accumulate and the light engine and LED driver will require replacement.

As customers who purchased the first release of Soffito* can attest, the upgrade pathway is simple and cost effective. It includes the light engine and driver for a fraction of the cost of a new fitting and installs in minutes and as noted above is fitted without breaking the seal on the room below.

When the time is right, upgrades are guaranteed to deliver the latest performance benefits and re-set the product warranty. So specifiers can be confident that their customers will remain fully supported for the long term with minimal disruption to complex clean room applications.

The SUP-HE kit-set, delivers all of the performance enhancements of the latest HE Chipset, optional upgrade to Ra95, without the need to replace the fitting. The Kit set was released in advance of the original models specified service life (65,000 Hrs to L70)

More Details

Installation Guides

SFO-VB-SS. Step by step guide to installing the Isollux Soffito Vented Box Kit

SFO-MB-SS. Step by step guide to installing the Isollux Mounted Box Kit

SFO-FK-SS. Step by step guide to installing the Isollux Soffito Flashing Kit

Packing and Shipping Information

SOFFITO HE:

Carton Weight: 12.2kg

Carton Dimensions: 73cm x 74cm x 21cm

Units Per Carton: 1

Product Net Weight: 10kg

SOFFITO Flashing Kit SFO-VB-SS-WF:

Carton Weight: 14.4kg

Carton Dimensions: 68cm x 69cm x 36cm

Units Per Carton: 1

Product Net Weight: 12kg

SOFFITO Flashing Kit SFO-FK-SS:

Carton Weight: 4.6kg

Carton Dimensions: 68cm x 67cm x 13cm

Units Per Carton: 1

Product Net Weight: 4kg

SOFFITO Flashing Kit SFO-VB-SS-NF:

Carton Weight: 13.8kg

Carton Dimensions: 67cm x 67cm x 36cm

Units Per Carton: 1

Product Net Weight: 12kg

SOFFITO Flashing Kit SFO-MB-SS:

Carton Weight: 8.9kg

Carton Dimensions: 73cm x 73cm x 19cm

Units Per Carton: 1

Product Net Weight: 8kg

*All sizes and weights are for shipping and delivery purposes only and can to change depending on specification. For an exact size and weight contact Isollux directly.

Download: Brochures | Instructions | IES Files

Soffito Brochure

*HE Chipset L90 Lifetime calculated using 9,000hr independent LM80 photometry report, citing zero failures, using the Energy Star TM-21 protocol. Calculations are based on ambient temperatures of 25ºC. Assumes driver replacement as routine maintenance event with driver replacement schedules subject to, power quality, frequency of switching cycles and average to peak ambient operating temperatures. Assumes driver replacement at midpoint of lifecycle, with the calculated MTFB 192.2K hrs min. MIL-HDBK-217F (25°C) based on the 100W 1500mm TPA/TPH. Average driver life 62,000Hrs.